Can Your Medical Device Benefit from Conformal Coating?

As a contract manufacturer of electronics-based medical devices, we are always looking for ways to vertically integrate as many key processes as possible, especially those impacting product reliability. Our latest development towards this goal was to invest in an in-house conformal coating line that provides the final step for PCBAs requiring ruggedization.

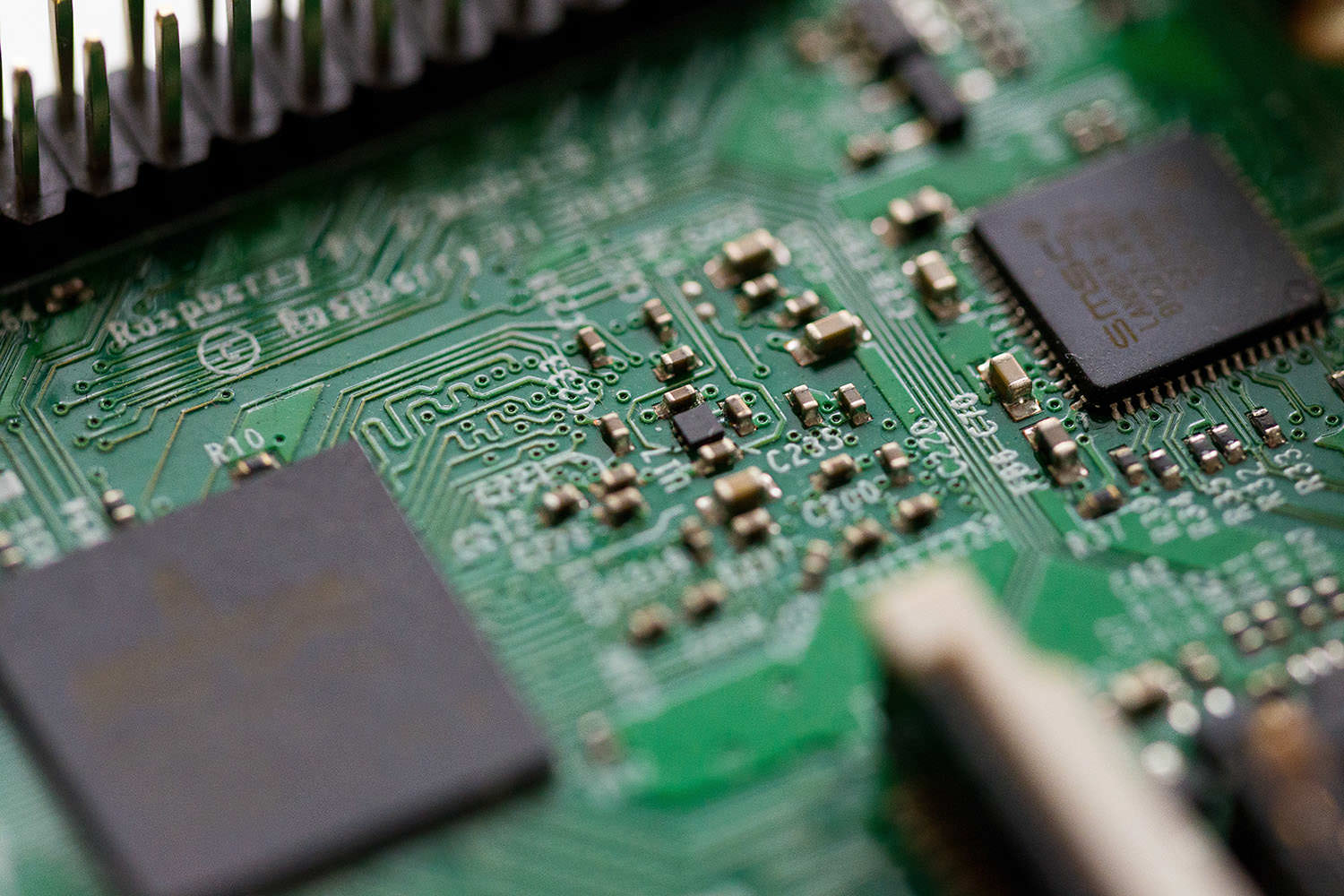

Conformal coatings are thin layers of polymeric film that conform closely to the contours of three-dimensional parts or products, offering protection from outside contaminants and forces – such as dust, corrosion, moisture, chemicals, abrasion and temperature fluctuations – that could otherwise impede device functionality. Regarded as a significant manufacturing innovation, conformal coatings have improved steadily over the last decade and are now widely seen as one of the best ways to increase the durability and service life of medical grade products.

Options and Benefits

Our customers can choose from acrylic, silicone, parylene C and parylene F conformal coatings, each with unique advantages that suit specific applications:

- Acrylic provides a basic level of protection at a relatively low cost, and it is easier to remove or rework than other surface treatments should repairs be needed.

- Silicone is a flexible, resilient, moisture and chemical resistant resin that protects against high and low temperatures, with a use range of -45 oC to +150 oC .

- Parylene is a biocompatible crystalline polymer that won’t affect or in any way interfere with devices operating in close proximity, making it the preferred choice for class III handheld and FDA approved implantable medical devices, as well as for printed circuit boards (PCBs) found inside complex mechatronic devices. It offers best in class protection against chemicals, moisture and extreme temperatures, with a use range of -270 oC to +250 o

- Vapor deposition provides a uniform, pinhole-free film that penetrates miniscule surface crevices, perfectly suiting it to the small, densely packed PCB components of complex mechatronic devices. It is also non-toxic, resistant to solvents, exceedingly strong and can be applied as thinly as 0.5 microns, making parylene the closest conformal alternative to a nano-coating.

The table below compares the benefits of each conformal coating we offer.

| Characteristic Type | Acrylic | Silicone | Parylene |

|---|---|---|---|

| Coating quality | Good | Good | Excellent |

| Chemical resistance | Good | Good | Excellent |

| Thermal cycling | Fair | Excellent | Excellent |

| Adhesion | Good | Excellent | Excellent |

| Abrasion resistance | Good | Fair | Good |

| Water resistance | Fair | Good | Excellent |

| Application process | Spray | Spray | Vacuum deposition |

| Curing required | Yes | Yes | No |

A comparison of Paramit’s conformal coatings.

State-of-the-Art Facilities

All of our conformal coatings are applied in our new state-of-the-art facility, which houses the latest generation of Nordson and VSI automated application equipment. This is complemented by our silicone gel potting capabilities, as well as a plasma pre-treatment service that modifies the chemical structure of surfaces to improve the surface tension, adhesion, quality and lifespan of any applied coating. We take quality control extremely seriously at Paramit, and great care is taken to avoid contamination during the coating process. If components or PCBs are exposed to silicone prior to soldering, residual particles can interfere with the process and lead to defects. That’s why we house our various coating operations in separate rooms, with an inner negative-pressure room used for silicone applications and an outer positive-pressure room reserved for other uses. This allows the inner room to act like a giant vacuum, preventing silicone spray from escaping into the outer room and wider facility.

Specialized selective spray and curing machinery on Paramit’s new Nordson ASYMTEK Panorama™ conformal coating line produces rapid and consistent acrylic and silicone coatings.

Parylene is deposited as a vapor or mist inside a sealed VSI vacuum chamber, producing an ultra-thin, uniform and defect-free coating.

Your Trusted Partner

Coatings are just one of our wide range of unique offerings, and our team of skilled engineers and technicians are fully equipped to assist customers during all stages of the new product introduction process, including the transition into manufacturing. We are innovative problem solvers who thoroughly understand our customers’ individual needs, along with the unique set of complexities and constraints associated with the medical device and life sciences industries. We share a commitment to excellence and are singularly focused on helping our customers successfully bring their products to market.

Paramit’s conformal coating rooms.