Mechanical

- Mechanical design utilizing SolidWorks

- Finite Element Analysis (FEA) and CFD analysis

- Motion control utilizing belts/pulleys, leadscrews, linear bearings with steppers, servos and piezo drives

- Fluidics and pneumatics including all types of pumps, valves, pipettes, pneumatic cylinders, accumulators, vacuum pumps

- Thermal Analysis and design for incubators, chillers, thermal cyclers

- Systems Engineering

- Airflow analysis and testing

- Shock and vibration analysis and testing

- Design for reliability, serviceability and manufacturability

Optics

- Optical system and optical component design capabilities

- Sequential and non-sequential Zemax modeling

- Thermal and opto-mechanical Monte Carlo tolerance analysis

- Experience with fluorescence, chemiluminescence, absorbance, and Raman systems

- Experience with high resolution imaging systems

- Breadboard and prototype feasibility construction, testing and evaluation

- DFM and rapid transfer to manufacturing

- Optical component mounting and isolation

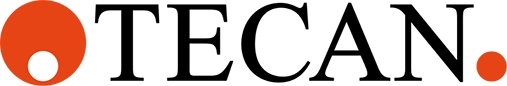

Electrical

- Hardware/firmware system architecture and design

- PCB layout and cable harness design

- Embedded system design (SBC, microcontroller, DSP/FPGA/CPLD)

- Electromechanical devices control and implementation (valves, pumps, sensors)

- Communication interfaces and protocols (serial, parallel, Ethernet, RF, IR, others)

- Robotic (motion) control systems and stepper implementation

- Thermal system development utilizing resistive heaters and TECs

- Electro-optical design (LED, laser, PMT, APD, others)

Software

- Quick turn prototypes for early stage feasibility/testing using Python scripting environments and command line interface tools on Linux or Windows

- Design and development of image processing algorithms, signal processing, and closed loop control algorithms for motion (positioning), temperature, pressure, power, etc.

- Experience with SW risk management and design controls which conform closely to ANSI/AAMI/IEC 62304 standards

- Experience using languages, operating systems and platforms to fit the customers device needs, such as: C, C++, C#, Linux, Windows IOT and cloud based technologies such as Azure and AWS

- Experience with the use of commercially available single-board computers (SBC) for instrument control

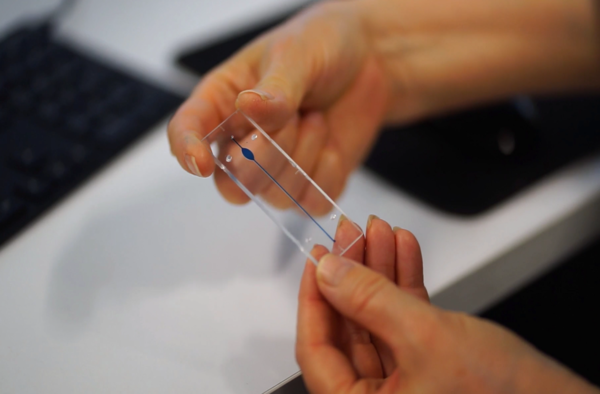

Consumables

- Microfluidics modeling & design of channels smaller than 1 mm

- Devices including chips, cartridges & micro-pneumatic systems

- Valves, pumps, centrifugation designs for microfluidics

- Surface modification for chemistry or fluidic effects

- On-board reagents: liquid and dried

- Prototype injection molding

- Blister packs: thermoformed and cold formed

- Foil and film sealing of cartridges and reagent vials

- Expertise in ultrasonic welding and leak testing

- Reagent vial design, liquid and dry, pierceable and peelable seals

- Vacuum oven for preliminary stability testing