Rapid Fabrication and Assembly

Instruments and Consumables

In-house fabrication means quick turn-around times on prototypes and reduced development time.

We understand the importance of getting your product to market fast. To minimize our reliance on external suppliers we’ve invested in fabrication equipment such as CNC milling, 3D Printing, and laser cutting. These investments are continuing as we broaden our capabilities specific to the needs of point of use devices and benchtop instruments.

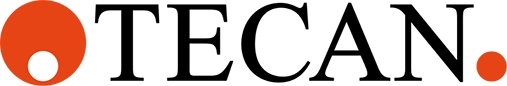

3D Printing

Formlabs Form 2

Prints 20+ materials:

- Stereolithography (SLA) 3D printing uses a laser to cure solid isotropic parts from a liquid photopolymer resin

xx

Stratasys Objet30

Prints cosmetic parts:

- Colors

- Elastomers

- Clear parts

xx

MARKFORGED X7

Prints structural plastic (fiberglass, kevlar or carbon-fiber filled)

- Industrial grade manufacturing jigs, jaws, tools and fixtures

- Capable of printing parts stronger than machined aluminum

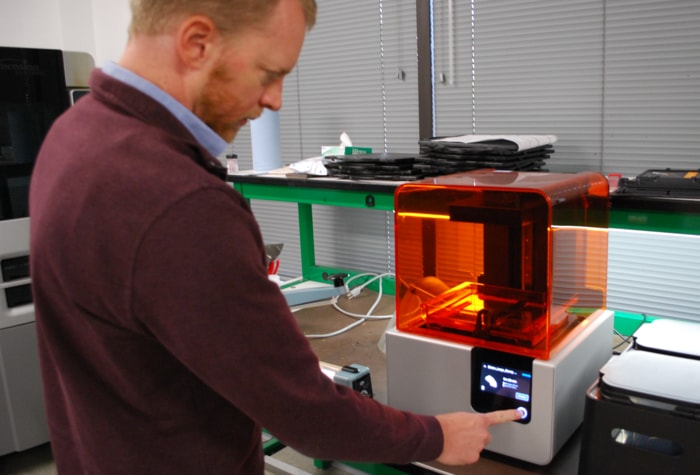

Molding Equipment

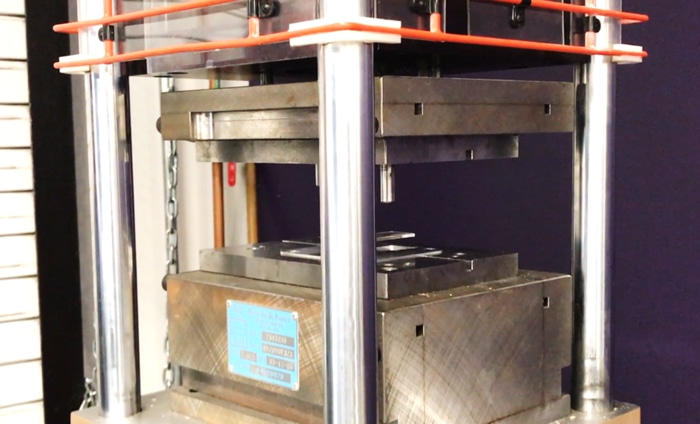

CNC Milling–Haas DM-1

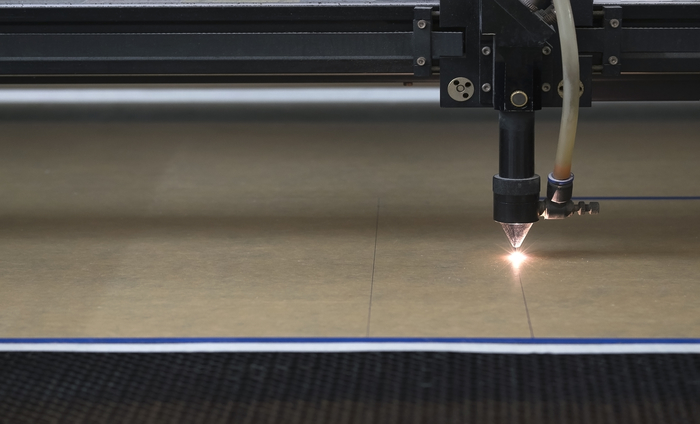

Laser Cutting–Trotec Speedy 400

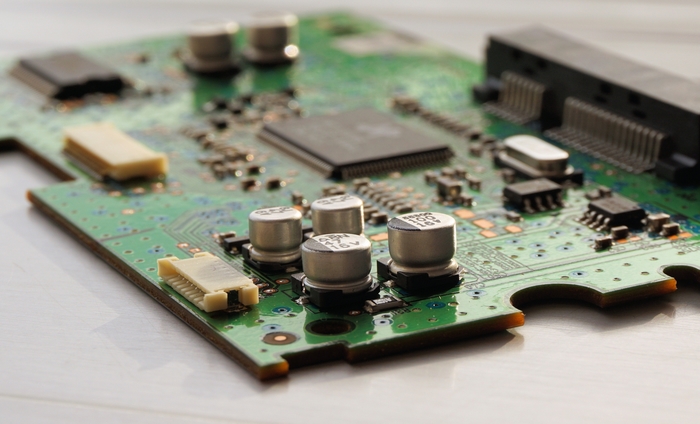

PCB Assembly

Our manufacturing facility is just around the block from our development building. We have four SMT lines and advanced inspection equipment well suited for quick turn prototyping. We reserve capacity for our instrument customers and product development programs, ensuring that electronics are never a bottleneck for instrument engineering builds.

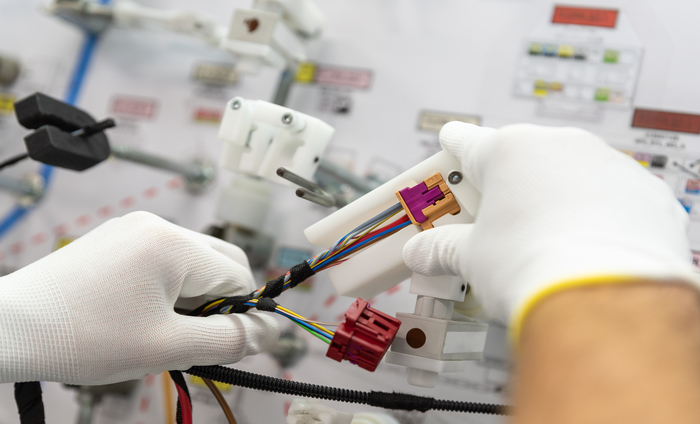

Cable Harness Assembly

We design and build cable assemblies, but should your instrument be cable assembly intensive we augment our internal capacity with an industry leading cable specialist located a few blocks away.